![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

QT12-15

Model:

QT12-15

![]() Pallet Size:

1400x880mm

Pallet Size:

1400x880mm

![]() Vibration:

Table Vibration

Vibration:

Table Vibration

![]() Rating Pressure:

21Mpa

Rating Pressure:

21Mpa

![]() Cycle time:

15-22s

Cycle time:

15-22s

![]() Motors Power:

63KW For Main forming machine parts only with material conveyor belt

Motors Power:

63KW For Main forming machine parts only with material conveyor belt

![]() Vibration motor:

2x15KW

Vibration motor:

2x15KW

![]() Machine Dimensions:

11000x2300x2600mm

Machine Dimensions:

11000x2300x2600mm

![]() Gross Weight:

About 12T

Gross Weight:

About 12T

![]() Raw Materials:

crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes

Raw Materials:

crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes

![]() Applied Products:

concrete blocks, solid/hollow/cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, edgers, kerbstones, grass blocks, slope blocks, interlocking blocks, etc.

Applied Products:

concrete blocks, solid/hollow/cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, edgers, kerbstones, grass blocks, slope blocks, interlocking blocks, etc.

![]() Certification:

ISO;CE;SGS

Certification:

ISO;CE;SGS

![]() Place of Origin:

CHINA.

Place of Origin:

CHINA.

![]() Trading Method:

FOB/CIF/EXW Xiamen Port

Trading Method:

FOB/CIF/EXW Xiamen Port

Product Description:

Hawen QT12-15 Automatic Hydraulic Hollow Block Production Line Interlocking Paver Machine is a state-of-the-art construction machinery designed for efficient and high-quality production of hollow blocks and interlocking pavers.

With the pallet size at 1400x900mm,it is used for big-scale production.

This machine is equipped with advanced hydraulic technology and automation features to streamline the production process and ensure precision in block and paver manufacturing.

Technical Features:

1. Hydraulic System: The machine utilizes a powerful hydraulic system for pressing and forming hollow blocks and interlocking pavers, providing consistent pressure and reliable performance.

2. Automation: The production line incorporates automated controls to manage material feeding, molding, and stacking, reducing manual labor and enhancing production efficiency.

3. Customizable Molds: The machine can accommodate a variety of mold designs to produce different sizes and shapes of hollow blocks and interlocking pavers, offering versatility in construction applications.

4. High Capacity: With its efficient design and robust construction, this machine can produce a large volume of hollow blocks and interlocking pavers in a short period, catering to the demands of construction projects.

Brick making flow chart introduction

|

NO. |

Name of Machine |

Note |

|

1 |

Batching machine |

Qty. Of strorage bin can be customized |

|

2 |

Skip hoist for Concrete mixer |

Another option: Conveyor belt |

|

3 |

Cement scale |

|

|

4 |

Screw conveyor |

|

|

5 |

Cement Silo |

Can be prepared by customer locally |

|

6 |

Conveyor belt for aggregate material |

|

|

7 |

Block making machine |

|

|

8 |

Face material conveyor belt |

|

|

9 |

Face material mixer |

|

|

10 |

Automatic block stacker |

|

|

11 |

Hydraulic station |

|

|

12 |

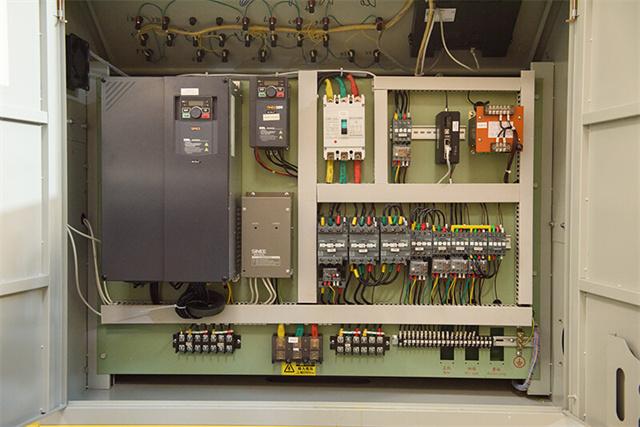

Control system for batching and mixing |

Optional |

|

13 |

Control system for block machine |

|

|

Note: It requires 1500-2000pcs of production pallet for production |

||

The Automatic Hydraulic Hollow Block Production Line Interlocking Paver Machine is suitable for various construction applications, including residential, commercial, and industrial projects. It is ideal for producing building materials such as boundary walls, retaining walls, pavements, and landscaping elements.

Capacity Sheet for QT12 Automatic block making plant

No.

Name

Dimension (mm)

( LxWxH)

Number of block per Pallet

Block /1hour

Estimated

Block /8hours

Estimated

1

Hollow block

400x200x200mm

12

2160

17,280

2

Hollow block

390x140x200mm

16

2,880

23000

3

Hollow block

390x90x190mm

24

4300

34400

4

Solid block

400x150x200mm

12

2,160

17,280

5

Solid brick

230x110x75mm

42

6,700

53,600

6

Stock brick

200x100x70mm

60

14,400

115,200

7

Maxie brick

290x90x140mm

32

7680

61440

8

Holland Paver

200x100x60/80mm

42

7500

60000

9

Interlocking paver

200x100xx60/80mm

42

7500

60000

The Automatic Hollow Solid Cement Block Machine And Paver Production Line is a cutting-edge solution designed to meet the increasing demand for high-quality and efficient cement block a...

QT4-15 Cement Solid Brick Production Line Interlocking Paver Machine is a state-of-the-art industrial equipment designed for efficient and automated production of cement solid bricks an...

QT15-15Fully Automatic Concrete Kerbstone Block Machine Paver Equipment is alarge-scaleindustrial machine designed for the efficient production of concrete kerbstones, blocks, and paver...

Interlocking paver mould is a critical component in the construction and manufacturing of interlocking concrete pavers. These molds are used to create the unique shapes and designs that...