Author:HAWEN Block MachineFROM:Brick Production Machine Manufacturer TIME:2024-03-14

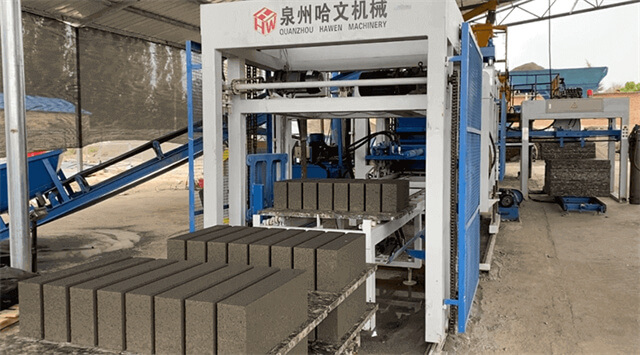

Manual block making machines have been used for decades to produce concrete blocks for construction purposes. These machines are designed to produce interlocking bricks, paving blocks, and hollow blocks that can be used to construct both residential and commercial buildings. In this article, we will explore the manual block making machine, its components, and how it works.

A manual block making machine is a simple device that does not require any electricity or fuel to operate. It consists of a mold box, a hand-operated lever, and a tamper. The mold box is made of steel or cast iron and is used to hold the concrete mixture. The hand-operated lever is used to compress the concrete mixture in the mold box, while the tamper is used to smooth the surface of the block.

The main components of a manual block making machine include:

To use a manual block making machine, first, mix the concrete mixture and pour it into the mold box. Next, use the hand-operated lever to compress the mixture. After that, use the tamper to smooth the surface of the block. Finally, lift the mold box using the handle and slide out the block. Repeat this process to produce more blocks.

Some advantages of using a manual block making machine include:

Some disadvantages of using a manual block making machine include:

To ensure that the manual block making machine is in good working condition, regular maintenance is required. Some maintenance tips include:

You can buy a manual block making machine from brick-making machine suppliers in your local area or online. Look for a reputable supplier who can provide after-sale services and technical support.

In conclusion, a manual block making machine is a simple device used to produce concrete blocks for construction. While it has some advantages, it also has some disadvantages. Regular maintenance is required to ensure that the machine is in good working condition.