Introduction:

Tanzania is experiencing rapid urbanization, leading to an increasing demand for construction materials such as blocks and pavers. To meet this demand, a Tanzanian client sought a modern and efficient solution for block and paver production, leading them to invest in an automatic production line.

Client Background:

The client is a construction materials supplier based in Dar es Salaam, Tanzania, serving a wide range of construction projects across the country. With a commitment to quality and efficiency, they were seeking to upgrade their production capabilities to meet the growing market demand.

Challenges Faced:

1. Increasing demand for high-quality blocks and pavers due to rapid urbanization.

2. Manual production methods leading to inefficiency, high labor costs, and inconsistency in product quality.

3. Need for a reliable and automated solution to enhance production capacity and maintain a competitive edge in the market.

Solution Implemented:

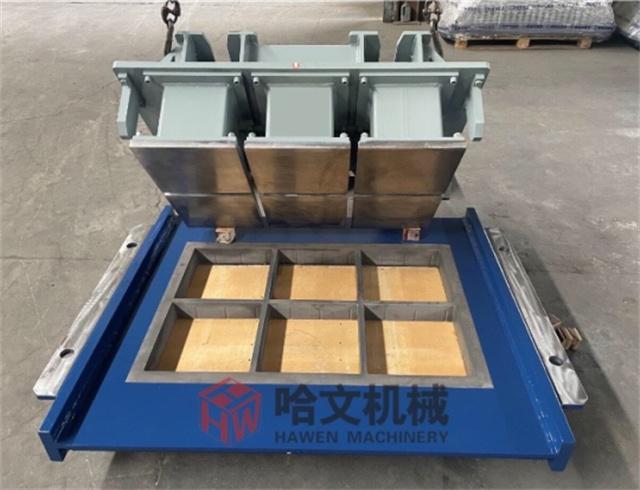

The client decided to invest in an automatic block and paver production line equipped with state-of-the-art machinery and technology. The production line included automated block-making machines, paver molds, robotic handling systems, and curing chambers. Additionally, the client opted for a system that offered customizable features to produce various block and paver designs, catering to diverse customer requirements.

Benefits Achieved:

1. Improved Production Efficiency: The automatic production line significantly increased the client's production capacity, reducing lead times and operational costs.

2. Consistent Product Quality: By automating the production process, the client achieved uniformity in block and paver dimensions, strength, and finish, enhancing their reputation for delivering high-quality products.

3. Cost Savings: Reduced labor requirements and minimized material wastage resulted in substantial cost savings for the client over time.

4. Market Competitiveness: With the ability to offer a diverse range of block and paver designs, the client gained a competitive edge in the market, attracting new customers and large-scale projects.

Conclusion:

By embracing modern technology and automation, the Tanzanian client successfully transformed their block and paver production capabilities, meeting the surging demand for construction materials in the region.

The investment in an automatic production line not only enhanced their operational efficiency but also positioned them as a leading supplier of quality construction materials in Tanzania's burgeoning construction industry.