Author:HAWEN Block MachineFROM:Brick Production Machine Manufacturer TIME:2024-03-18

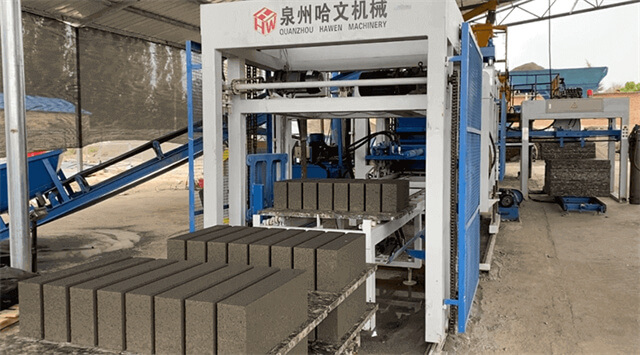

Choosing the right automatic hollow block machine is essential for anyone involved in the construction industry. With the increasing demand for hollow blocks, it is crucial to invest in a reliable and efficient machine that can produce high-quality blocks. However, with so many options available in the market, selecting the right machine can be a daunting task. In this article, we will discuss the key factors to consider when choosing an automatic hollow block machine.

The production capacity of the machine is one of the most important factors to consider. It determines how many blocks the machine can produce within a given time frame. Depending on your requirements and the scale of your construction projects, you need to choose a machine that can meet your production needs. Consider the number of blocks you need per day and select a machine that can handle that volume efficiently.

The automation level of the machine determines how much manual labor is required to operate it. Fully automatic machines are highly desirable as they can significantly reduce labor costs and improve productivity. These machines have automated systems for feeding raw materials, compacting, molding, and stacking the blocks. However, they may come at a higher price compared to semi-automatic machines. Assess your budget and labor resources to determine the appropriate automation level.

Consider the specific size and design of hollow blocks you want to produce. Different machines have different molds that can accommodate various block sizes and designs. Ensure that the machine you choose has the necessary molds to cater to your specific requirements. Additionally, some machines allow for customization, giving you the flexibility to change block sizes and designs as needed.

Investing in a high-quality and durable machine is crucial for long-term success. Look for machines that are made from robust materials, such as steel, which can withstand the heavy workload and last for years. Read customer reviews and testimonials to assess the reliability and performance of the machine. Additionally, check if the machine has suitable warranty coverage to protect your investment.

The power requirement of the machine and its energy efficiency are important considerations. Assess the power availability at your site and choose a machine that can operate within those parameters. Additionally, look for machines that are energy-efficient, as they can help reduce operational costs in the long run.

Choose a manufacturer or supplier that provides excellent after-sales service and support. A reliable supplier should offer technical assistance, spare parts, and maintenance services to ensure the smooth operation of the machine. This will minimize downtime and maximize productivity.

Consider the price of the machine and evaluate its return on investment (ROI). While it may be tempting to go for the cheapest option, it is essential to strike a balance between price and quality. Calculate the ROI based on the machine's production capacity, labor savings, and block quality. A machine with a higher upfront cost but lower operating costs and higher productivity may provide a better ROI in the long run.

Finally, research the reputation and experience of the manufacturer or supplier. Look for companies with a proven track record in the industry. Check if they have a strong customer base and positive reviews. A reputable company is more likely to provide reliable machines and excellent customer service.

Choosing the right automatic hollow block machine is crucial for the success of your construction projects. Consider factors such as production capacity, automation level, block size and design, quality and durability, power and energy efficiency, after-sales service, price, and reputation. By carefully evaluating these factors, you can select a machine that meets your requirements and provides a strong return on investment.